Sumitomo Chemical, the Japan-based chemical giant, is reported to have successfully developed new technologies to facilitate more cost efficient OLED display manufacture. According to Nikkei, the new materials and equipment the company introduced could possibly bring down the current production cost of OLED panels by 50%, which is able to further reduce the selling prices of OLED TVs and expand the penetration of OLED products.

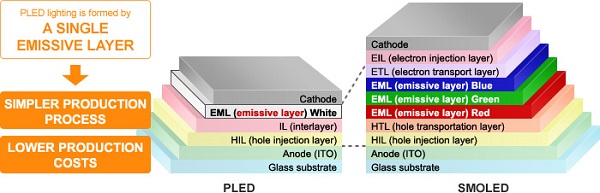

Sumitomo Chemical introduced self-developed macromolecular materials formulated for the emissive layers in OLED panels. With the new materials, OLED panels can be manufactured through efficient inkjet printing technology. Compared with small molecule organic LED (SMOLED), Sumitomo Chemical’s ‘PLED’ technology integrates red, green and blue emissive layers into a single white emitter that enables simpler OLED printing processes.

The mainstream process the majority of OLED manufacturers adopt so far is the evaporation-based process, in which red, green and blue emitters are evaporated and deposited onto glass substrates under vacuum. It; however, requires expensive equipment and fails to keep most of the materials, reflecting fairly high production cost. On the other, the OLED printing process, though with lower manufacturing cost, also meets technological hurdles during the coating process of large-sized panel production.

The chemical company is able to print its single emissive layers onto glass substrates evenly. To put the PLED technology into practice, it also constructed new printing equipment.

New OLED technology is said to be co-developed by Sumitomo Chemical, JOLED, and overseas display makers. JOLED’s 21.6 inch OLED displays for medical monitors, to hit shelves in fall 2017, first adopted the new materials. Sumitomo Chemical also promoted this new technology to LG Display to use it in the Korean firm's OLED TVs expected to enter the MP stage in 2019.

JOLED on 17th May announced the first printed 4K OLED display that came in a size of 21.6 inches. It started offering samples for medical monitors and attempted to expand the product’s application base to television, gaming and other uses.

JOLED already received orders from Sony. Nobuhiro Higashiiriki, CEO of Japan Display Inc. expressed on the previous press conference that the OLED printing technology is anticipated to be widely used in the production of mid-sized displays in the future.

CN

TW

EN

CN

TW

EN