Growth in the Internet of Things is having a profound effect on the way we live – but its continuing success depends on effective, practical manufacturing and installation strategies as much as its bold new design and integration concepts.

The Internet of Things (IoT) is now very much a reality, with new applications appearing daily – from wearable devices to city-wide traffic management systems. Full IoT implementations are often about Big Data analysis of large sensor arrays, giving us deeper insight and better ability to control our environment than previously possible.

However, IoT technology is giving us better control in simpler applications as well, with lighting systems being a prime example. Modern installations increasingly use LED lighting technology – LEDs were projected to have had 39% of the global lighting market share by 2015, according to Statista. Well-known reasons for this include the technology’s power efficiency and operational longevity, but LED lights offer another key advantage too; controllability. They turn on and off instantly, and have an infinitely controllable and dimmable output, with no flickering. Lighting effects can be accurately defined and implemented, covering desired areas with no wastage.

|

|

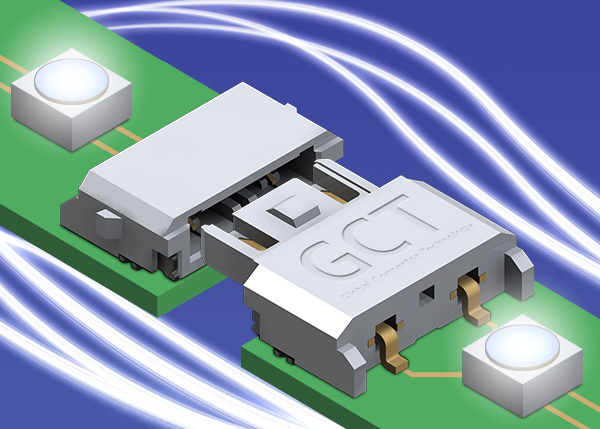

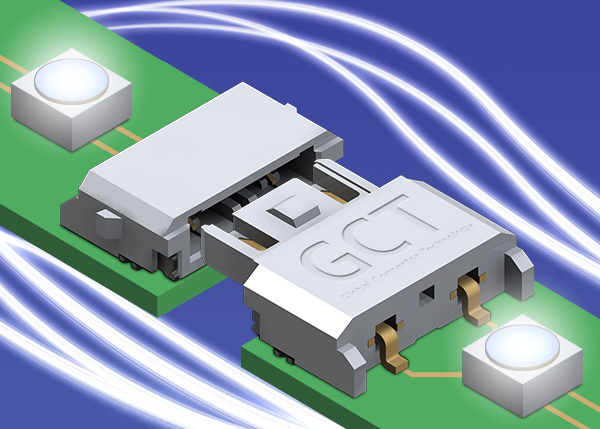

(Image: Global Connector Technology) |

Another major factor is that LED luminaires operate from low voltage DC supplies, rather than AC mains, so they must be fed from an AC/DC power adaptor, usually known as a driver. Today, some of these drivers have become smart, and can be connected to lighting industry standard networks such as DALI (Digital Addressable Lighting Interface). This means that they, along with the LED luminaires they feed, can be driven remotely by a human or automated controller.

Retail applications such as point of sale displays are realising these controllable LED lighting benefits, with implementations using flexible LED lighting strips. As LED products, they provide an energy efficient lighting source with low heat output; this is especially important within the confined space of an advertising display light box. They start up instantly with a crisp light, and are available in a variety of colours.

However, despite these attractive features, LED lighting strips would not enjoy sustained success unless they were also easy to install, and reliable – and the choice of electrical connector contributes significantly to these attributes.

GCT’s new surface mount wire trap connectors, for example, are designed specifically for LED lighting strip applications. Engineers can choose either a 2.4mm or a 4.0mm pitch, depending on space constraints and current rating requirements. These options, together with a choice of 1,2 or 3 contacts, allow an efficient, compact and unobtrusive design. The natural LCP insulating material provides a discrete, aesthetic match to lighting strip PCB colours. Light absorption and shadowing is reduced, with minimal likelihood of light reflections where white PCBs are used.

These connectors save time during installation, maintenance and repair, as stripped cables may be inserted and terminated direct to the contacts in one simple action. The cables can be removed with equal ease, and without need for special expertise, simply by pushing a slider button.

High-performance lighting configurations are facilitated with good connector current ratings; 8A per contact with 18 AWG solid cable on the BJ302 4mm product, and 4A per contact with 22 AWG solid cable on the BL300 2.4mm version. At -40°C to +105°C, the connector’s operating temperature ratings are also good.

Design and planning as well as installation are facilitated, as comprehensive documentation covers suitable cable types, cable preparation information, wire strip length, insertion angles and wire extraction are all readily available to access and download from the GCT website.

GCT’s wire trap connectors also simplify bills of materials, drawings and assembly procedures, as a single connector type is all that’s needed to cover every PCB-PCB and PCB-power supply connection.

Overall, these reliable, robust and easy to use wire trap connectors help LED lighting strips to reach their true potential throughout the design, installation and operation phases.

CN

TW

EN

CN

TW

EN