Panasonic Corporation announced it has developed a light diffusion type polypropylene (PP) resin molding compound, called “FULL BRIGHT”*1 PP, which can extend the operating life of LEDs. The industry’s first*2introduction of a material applicable for injection stretch blow molding enables the formation of complex shapes and contributes to greater product design freedom for customers.

|

|

Light Diffusion Polypropylene Resin Molding Compounds, "FULL BRIGHT" PP. (Panasonic/LEDinside) |

This material has the following advantages.

1. In addition to injection molding, this material can also be used for injection stretch blow molding process that was previously believed to be difficult using conventional light diffusion PP resin molding compounds, enabling customers to form complex shapes with greater freedom based on individual customer applications.

• Ability to produce 0.5-mm thin molding, which was previously unachievable; achieved less than 10% thickness accuracy by processing; company’s previously used material*3 generated a hole when a product was blown to a 0.5-mm thickness.

2. Conquered the previous weakness of light resistance of the conventional PP resin molding compounds and achieved excellent resistance to chemicals, contribute to extend the operating life of LED lighting.

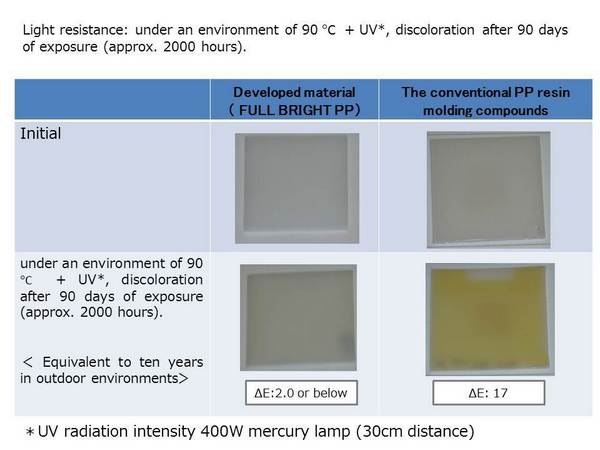

• Light resistance: under an environment of 90°C+ UV*4, discoloration after 90 days of exposure (approx. 2000 hours).

ΔE:2.0 or below, which is equivalent to ten years in outdoor environments; company’s previous material*3 was ΔE: 17.

|

|

Comparison of light resistance (a result of the accelerated test). |

3. Material characteristics of low specific gravity contribute to lightweight design of LED lighting devices.

*1) “FULL BRIGHT” is a trademark of the Panasonic Corporation.

*2) As the light diffusion PP resin molding compounds applicable to injection stretch blow molding as of April 5, 2016 (surveyed by the company).

*3) The conventional PP resin molding compounds.

*4) UV radiation intensity 400W mercury lamp (30cm distance)

Applications

LED lighting (automotive interior lighting, outdoor sign boards, store lighting, and water-related lighting), digital signage, etc.

CN

TW

EN

CN

TW

EN