Osram's new LED chip factory in Kulim, Malaysia, begins operation on time. "We are both on schedule and within budget," pointed out Olaf Berlien, CEO of OSRAM Licht AG, during the opening ceremony in Kulim on Thursday. "Given our enormous recent growth rates of 19 percent in the LED business, we are pleased to have the new production capacities. Our investment in Kulim also attests to the technology shift and our transition to becoming a high-tech corporation: At the beginning of this decade, conventional lighting still accounted for 80 percent of Osram's business. Today, two-thirds of our sales are based on optical semiconductors."

|

|

(Image: Osram) |

In November 2015, as part of its Diamond innovation and growth initiative, Osram announced plans to build the new LED chip factory in Kulim and to have it up and running by the end of 2017. The modular, expandable factory has now been put into operation just two years after the announcement and one and a half years after the ground-breaking ceremony. A total of EUR370 million were invested in the first stage of completion. Osram can expand the factory in two additional stages, entailing total investment costs of up to one billion Euros -- including expansion of LED assembly capacities in Osram's global factory alliance.

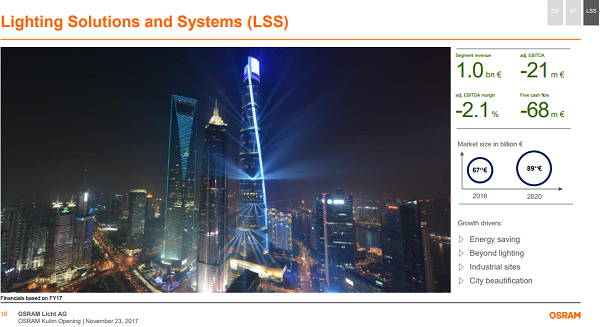

Aldo Kamper, CEO of OSRAM Opto Semiconductors business unit, underscores the enormous production capacity in Kulim: "With one week's production we could completely retrofit the street lighting of the metropolises New York, Rio, Hong Kong and Berlin with LEDs." To upgrade the entire street lighting worldwide, Kulim would have to produce LEDs five and a half years long exclusively for this purpose. Energy savings of up to 80 percent, compared to conventional street lights, can be achieved with LED lighting. In addition, LED has better light color stability and can be more quickly dimmed and adjusted, so that empty streets or sidewalks do not always have to be illuminated with full brightness.

|

|

(Source: Osram) |

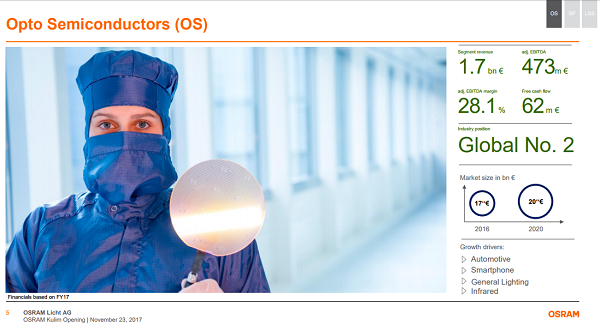

The Osram factory in Kulim will produce blue LED chips which, by means of a converter layer, can generate white light. They are produced for general lighting purposes, such as the previously mentioned public street lighting, but also for facade lighting, private and commercial interior and exterior lighting, or for billboards - as well as for special applications such as horticulture lights. The global LED market for general lighting is estimated to be EUR6 billion in 2018, roughly six percent of which is for street lighting. An average growth rate in the market of seven percent per annum is foreseen through 2020. The overall market for optoelectronic components - including general lighting - will be EUR17.5 billion in 2018.

|

|

(Source: Osram) |

The plan is to also produce LED chips in Kulim in the medium term for premium applications, such as automotive lighting and video projection. Thanks to the new facility at a green-field location, no compromises had to be made in the design of the factory, in addition it features the latest technology. In comparison with the 4 inch technology, the production systems for 6 inch wafers produce 125 percent more LED chips per wafer in a single cycle.

|

|

(Source: Osram) |

Osram is currently investing worldwide in the expansion of the existing six sites in its LED production network. Therefore, Osram is also expanding its plant in Regensburg, which currently has about 2,500 employees, and will additionally hire up to 1,000 employees. Premium LED chips and laser diodes, which are used, for example, in high-quality car headlights, will be manufactured there as well as infrared diodes for sensors that can be used in applications including facial recognition in mobile phones, or in cars for intelligent assistance systems (such as proximity control).

Furthermore, Osram will be expanding its site in Schwabmuenchen. In the future, Osram will manufacture LED primary materials in clean rooms there. In addition, Osram also has another plant for LED primary products in the U.S. city of Exeter. In Wuxi, China, Osram is expanding its capacity for assembling LED chips into complete LEDs - i.e. light-emitting diodes with a housing and partly with primary optics too. In Penang, Malaysia, located near Kulim, LED chips are also manufactured and assembled.

CN

TW

EN

CN

TW

EN