|

|

The LED industry has been in a slump for the past 2-3 years, but 2013 marked a turning point. Rise in LED lighting demands brought new opportunities for the industry, but low price and low cost trend caused many manufacturers to incur losses and struggle financially. LED chip manufacturers with high capital expenditures were the most affected, with many still stuck in the situation. Chip scale packaging (CSP) products are the industry's latest attempt to lowering costs, as the technology is able to eliminate wiring bonding and lead frames during the production process. The product has become a hot topic in the industry upon its release. With improving CSP products technology and rising market acceptance, CSP developments in 2014 are highly anticipated by the industry.

|

|

|

Overview Overview |

|

Unsurprisingly, CSP products drew a lot of attention from the industry in 2013. However, CSP is not a new technology. LED manufacturers had already invested R&D resources early on. As the technology and market matures, one could say that 2013 was the year of CSP components. Large manufacturers such as Toshiba, Cree, and Philips Lumileds as well as major Taiwanese LED chip manufacturers Epistar, FOREPI, TSMC Solid State Lighting, Lextar, and package manufacturer Unistars were the first to develop CSP products. Korean manufacturers and Chinese manufactures are also competing to enter this market.

Majority of CSP products use flip-chips as a base and eliminate the wire bonding and lead frames, which allows the products to have luminosity on five sides and at wider angles. It also allows them to reduce the size. CSP can also be referred to as package free. Package free products name and definition has sparked discussions in the market with each manufacturer having their own perspective. Cree, Philips Lumileds and Unistars all launched CSP products, which is a concept that comes from the semiconductor industry. Epistar is highlighting Embedded LED Chip (ELC), TSMC SSL is promoting Phosphor on Die (PoD) and FOREPI's package free product can be defined as White Free Chip (WFC). CSP was the highlight of 2013. Following manufacturers launch of respective CSP products on the market, we can except more market diversity in 2014.

|

|

|

Epistar Unveils Package Free Chip Technology for LED-backlit TV Epistar Unveils Package Free Chip Technology for LED-backlit TV |

|

Taiwanese LED chip manufacturer, Epistar, recently showcased its latest Embedded LED Chip (ELC) technology. The new ELC product reduces lead frame and wire bonding, and only requires a chip, phosphor and glue, said Hsieh Ming-Hsun, VP, R&D, Epistar at the LED Technology Forum held in Taipei, Taiwan. As a result, the chip can directly use surface-mount technology (SMT). The ELC can be applied in advance onto backlight products, and possess advantages of wide light beam angles, continued Hsieh. There is an opportunity to omit secondary optical lenses in the future.

|

|

|

FOREPI Begins Package Free Chip R&D FOREPI Begins Package Free Chip R&D |

|

To welcome the LED lighting era, Taiwan LED chip manufacturer FOREPI Project Manager Li Renzhi stated that as the LED industry develops into a M shaped trend, high priced small volume products will occupy one end and large volume economic products the other. Continual LED chips price reduction has led to manufacturers entering package free wafer R&D. FOREPI launched package free chips with features of high luminous efficacy and large beam angles. The company plans to enter the LED market.

|

|

|

Philips Lumileds: Chip Scale Packaging for LEDs Philips Lumileds: Chip Scale Packaging for LEDs |

|

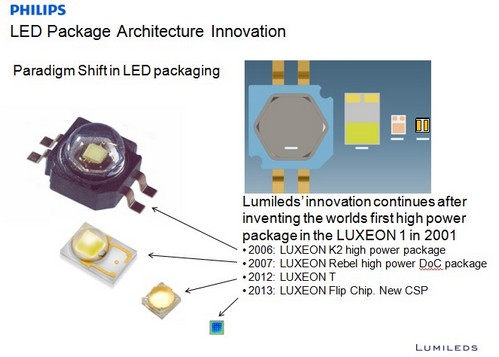

PhD. Bhardwaj Jyoti, Senior Vice President, R&D, Philips Lumileds gives detailed information about the development of chip scale package (CSP) technology in this article. CSP may be novel to the LED industry, but have been the mainstay of the semiconductor industry. Development of CSP in the Si ICs was driven by miniaturization, improved thermals, higher reliability, and simply the need to connect to an ever increasing pin-count on an ever shrinking die. CSP also enabled a reduction in device parasitic and allowed for ease of integration into Level 2 packaging. It is therefore a natural evolution for such packaging innovation to proliferate into other industries including the LED product space.

|

|

|

Unistars Mass Produces 1515 CSP LED Light Source Unistars Mass Produces 1515 CSP LED Light Source |

|

LED technology has made great leaps in 2013. As LED prices continue to fall, large LED manufacturers are focusing on packaging process and material to develop low cost technologies. "Package free technology" has no doubt become the most important technological breakthrough this year that has surprised the industry. Unistars has been using advanced wafer package technology, Chip Scale Package (CSP). The company has released its new CSP series product Mercury 1515 series, and is the first Taiwanese LED packager to mass produce CSP products.

|

|

|

|

|

|

TSMC Solid State Lighting Ltd and Xiamen Topstar Co., Ltd. will announce their strategic cooperation at the 2013 Hong Kong International Lighting Fair (Autumn Edition). Inaugurating the cooperation, a series of lighting products were released together. The new product series applies TSMC Solid State Lighting's industry-leading package-free PoD technology to Topstar's newest generation of lamp products. Topstar's renowned brand name and excellent manufacturing capability joining forces with TSMC Solid State Lighting's advanced LED technology create a strong partnership able to provide world-class products for the Chinese and global LED lighting markets.

|

|

|

|

Viewpoint

CSP products have successfully become the market topic in 2013. Changes in CSP product manufacturing, luminosity, and design flexibility have opened up new LED application possibilities. Releasing new technology and products allows LED manufactures to lower prices. Although, CSP products have created quite a stir on the market in 2013, very few products actually are on the market for sale. Early entry into mass production phase remains a hurdle for manufacturers. Intensifying competition in the CSP product market has lead to the upsurge of CSP products in 2013, which is anticipated to spread throughout 2014. |

|