Despite technological leaps in modern electronics, the quality of lighting they provide still leaves much room for improvement.

A collaborative team — led by Jian Li, an associate professor of materials science and engineering in the Ira A. Fulton Schools of Engineering at Arizona State University — aims to change that.

The team hopes to produce devices for lighting that will mimic natural light more precisely than previous technology, enabling users to see things more vividly and in healthier lighted environments, Li said.

|

|

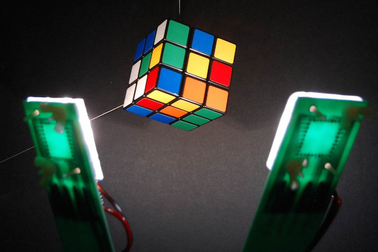

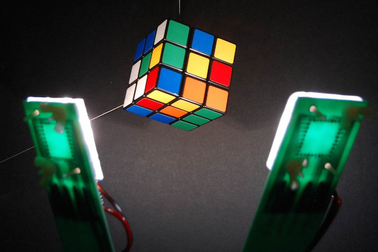

This image of single-doped organic light-emitting diodes (OLEDs) shining a high-quality white light on a Magic Cube shows how OLEDs can vividly illuminate the colors of the cube across the full range of the visible color spectrum from blue to green, yellow and red. ASU engineer Jian Li’s research team is working to develop a cost-effective solution for the next generation of solid-state lighting products based on OLED technologies. (Photo courtesy of Jian Li’s research group.) |

One area of research that promises solutions is focused on developing advanced organic light-emitting diodes — called OLEDs.

The new OLEDs would not emit ultraviolet (UV) light, which will not only enable clearer vision but also will prevent eyestrain that often results from continuing exposure to the UV light emitted by current devices, Li said.

Such OLEDs will particularly benefit museums, art galleries and similar places, since UV light inhibits the human eye in clearly discerning color variations and the texture of objects. Over time, UV light also actually dulls colors of paintings by causing slow decomposition of the paints and other materials.

Major advances in the technology would amount to “a very big milestone” in the ability to effectively light our world, said Li, who is on the faculty of the School for Engineering of Matter, Transport and Energy.

High priority for energy efficiency

Work on OLEDS led by Li in the past decade has attracted continuing interest from industry and government.

The most recent support is a grant providing $875,000 over two years from the U.S. Department of Energy to allow Li’s lab to expand its research and further develop its collaboration with Universal Display Corporation, a leading developer of electronic display and lighting technologies based on organic materials.

Li said the Department of Energy considers progress in OLEDs a high priority — a key part of its efforts to help the nation become more energy-efficient, diversify into renewable-energy resources and find ways to provide more affordable energy.

The next generations of OLED technology can be expected to enhance the lighting performance in all kinds of solid-state electronics — everything from lighting for parks, streets and sports facilities to digital watches, cellphones, television and computer screens, and flexible electronic displays, as well as home, commercial and industrial lighting.

Emitting pure white light

An organic light-emitting diode is a light-emitting diode (LED) that employs conjugated organic molecules to transport electrical charges and emit light in response to the electric current. The typical thickness of a whole OLED is less than 1 micrometer, which can be transparent and compatible with the flexible substrates.

“This technology will offer many benefits over our conventional lighting devices,” Li said.

Advanced OLEDs will enable more control of the brightness of lighting, along with providing more options to mold the shapes of the lighting devices, to pinpoint the direction and intensity of light, and to control the color of light.

Li’s research team is working to develop OLEDs that use a single emissive material to create a white emission — rather than more complex structures that rely on the use of combination of blue, green and red emissive materials — designed to emit a more operationally stable and pure white light than other lighting technologies.

Achieving this requires the design and utilization of a unique class of emissive materials that can produce a blue emission in a single molecular form and produce an orange emission with two molecules stacked on each other. The precise control of both the blue and orange emissions can produce a high-quality white light for indoor illumination.

Multidisciplinary research pursuit

If successful, the new OLED devices will be less complicated and less costly to manufacture, and offer increased efficiency and longer lifespans because they would need less power to operate. That accomplishment would effectively pave the path to relatively rapid commercialization, Li said.

The endeavor is a challenging one, but Li is confident his team has the multidisciplinary range of expertise to attain its goal. With Li, several graduate students and a postdoctoral researcher, they bring expertise in materials science and engineering, chemistry, physics, electrical engineering, process engineering and mechanical engineering.

Li also is helping ASU colleagues to further expand their own lighting research, and he’s pursuing related work as one of the principal investigators for the ASU-Army Flexible Electronic Display Initiative and as a leading researcher in the university’s Center for Photonics Innovation and the Advanced Photovoltaics Center.

Universal Display Corporation will help with building device prototypes and with product testing.

“By applying the combination of knowledge from these fields, we expect to make important progress,” Li said.

CN

TW

EN

CN

TW

EN