German semiconductor manufacturer, Azzurro LED Technologies, announced during a talk at ICNS-10 that the company’s technology has reached the capability of achieving “1 bin” GaN-on-Si LED wafers. While showing production values of less than 3 nm wavelength uniformity, the 1.0 nm result came straight from development. The record 1.0 nm result demonstrates the capability to achieving “1 bin” GaN-on-Si LED wafers.

After questions about achieving competitive brightness and efficiency levels have been answered by various GaN-on-Si contenders, the yield question has remained open. The large mismatch of crystal lattice structure and thermal expansion coefficient cause highly bowed LED wafers after and during growth. This in turn has a very big negative impact on uniformity levels for wavelength, forward voltage and output power. The company uses its proprietary and patented strain-engineering and growth technologies to overcome these obstacles.

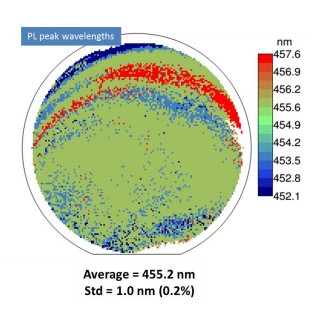

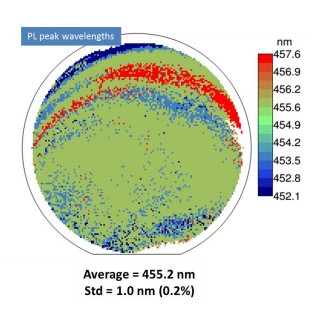

Breakthrough uniformity from production for wavelength (< 3 nm or 0.6%), forward voltage (1.3%) and output power (3.9%) for highly reduced binning were shown at the ICNS-10 in Washington D.C., U.S. together with excellent crystal quality values for 150 mm blue emission GaN-on-Si LED wafers (all values are standard deviation). At the same time equally impressive values for 200 mm LED wafers show the company's technological scalability. Manufacturability parameters like low bow (< 20 µm) and very good thickness uniformities (1.7%) are not compromised on. Based on these achievements the technical team continues to push for the ultimate “1 bin” wafer aim and demonstrated the benchmark result for wavelength with only 1.0 nm uniformity and a min/max value of 5 nm (one wavelength bin). (See graph below.)

|

|

Azzurro LED Technologies demonstration of the 1.0 nm wavelength on GaNon-Si LED technology. (Photo: Azzurro LED Technologies) |

Azzurro’s latest results from production and development clearly prove that in addition to the cost advantages from lower cost substrates and by using standard silicon fabs for LED chip processing GaNon-Si LED wafers with the right strain-engineering technology can also help reduce binning dramatically.

The company's co-founder and CMO, Alexander Loesing, who is also heading its LED Technologies business unit, commented on the results: “We are very proud of our team’s record 1.0 nm achievement. With these results we show that our GaN-on-Si technology can bring the LED industry closer to the aim of making “1 bin” LED wafers.”