Good news from the management of ASM Assembly Systems GmbH & Co. KG (formerly Siemens Electronics Assembly Systems) at the SIPLACE press conference in Shenzhen. SIPLACE COO in China, Herbert Hofmann, presented a whole series off innovative SIPLACE solutions for the following process steps: new product introduction (NPI), setup changeover and production run. Based on the globally leading SIPLACE placement platform, integrated hardware, software and service innovation will help especially electronics manufacturers in China and Asia to adapt their production more quickly, efficiently and reliably to fluctuating demand and rising customer requirements. Günter Lauber, CEO of ASM Assembly Systems, and W. K. Lee, CEO of new SIPLACE parent ASM Pacific Technology (ASMPT), reported on the company’s good performance and the progress made in integrating the SIPLACE team into the Singapore-based ASM group. Only eleven months after the takeover in January of this year and the final completion of the integration process in China, end of September 2011, the SIPLACE team is benefiting disproportionately from the industry’s growth, allowing it to account for a good part of ASMPT’s record results and almost one third of its revenues.

At the center of the SIPLACE press conference on November 30th 2011 was the progress made in integrating the company into the ASM group. ASM Pacific Technology (ASMPT) had acquired the SIPLACE team and its SMT business in January 2011 from Siemens and integrated it as a separate business unit under the ASM Assembly Systems name, finalizing with SIPLACE China end of September 2011.

Using synergies to add market share

In his presentation, Günter Lauber, CEO of the SIPLACE teams, pointed out the rapid success of this integration, for which he credited in part the industry experience of the ASM group, which has for many years been a leader in the backend/chip assembly segment with its solution for waver and chip production. According to Lauber, thanks to the new owner’s decision to keep the SIPLACE team in place along with its locations and its cluster organization, the company did not have to waste any time with restructurings in the current boom, but could focus on serving the needs of customers and markets. In a second integration phase, the SIPLACE team plans to gain additional market shares by exploiting its improved access to Asian markets, lowering its costs through shared sourcing and expanding its solution spectrum through new R&D initiatives.

SIPLACE China plays central role

In his presentation, Joe Poh, who heads SIPLACE’s operations in China, underscored the central role SIPLACE China plays in implementing the company’s growth strategy. Joe Poh’s team plays a special role as both SIPLACE’s representative on its most important market and as a “bridge“ in the integration of the two companies. “With its German engineering, SIPLACE has been a recognized as the technology leader and the No. 1 on the European market for many years, while ASM Pacific Technology is the world leader in backend solutions thanks to its leading position in Asia. By taking care of our local customers as SIPLACE China, we want to make sure that SIPLACE becomes the world’s leading placement machine maker over the medium term,” said Joe Poh about the importance of the Chinese market and the SIPLACE organization’s role in it. To accomplish this, the company is further improving its direct and competent support for Chinese electronics manufacturers by expanding its network of sales offices, service centers and technology, training and application centers. SIPLACE is also developing new products in close cooperation with customers in China and the rest of Asia.

Innovations for NPI, changeover and production run

Herbert Hofmann, China COO of ASM Assembly Systems offered detailed insights into his company’s current developments and innovations. In response to the concrete challenges facing electronics manufacturers in the areas of new product introductions, setup changeovers and volume production, Hofmann presented the latest solutions developed by SIPLACE’s engineers. The spectrum of innovations ranges from NPI solutions such as SIPLACE Smart Pin Support or SIPLACE Alternative Components to high-mix setup concepts such as Random Setup or Constant Table to general efficiency improvements with SIPLACE Smart GUI, SIPLACE LED Pairing or SIPLACE Nozzle ID Scanning. Hofmann underscored several times that modern SMT solutions are increasingly based on intelligently intertwined hardware, software and service components and that the SIPLACE team succeeded in making significant progress over its competitors in these fields in recent years.

ASM group delivers record results

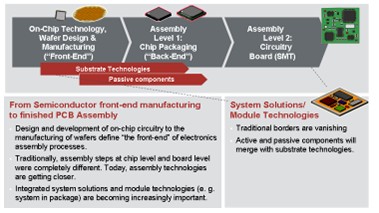

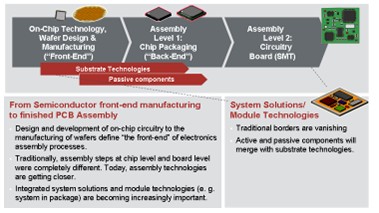

W. K. Lee, CEO of ASMPT, noted in his presentation that the integration of the SIPLACE team is progressing successfully also from the perspective of the parent company’s management team. From a strategic viewpoint, the acquisition of the SIPLACE team made the ASM group the only provider who can serve its customers in the electronics industry with expertise in the entire process chain from wafer production to chip assembly and packaging to SMT placement. ASMPT itself has been the global leader in chip assembly, lead frame and bonding equipment for the chip assembly and packaging fields since 2002. During the first nine months of 2011, the business with SIPLACE solutions was a significant factor in the group’s sales growth of 36.2 percent to US$ 1.336 billion, a new record.

W. K. pointed out that the group continues to target synergies by expanding its cooperation in the areas of component development and sourcing via shared in-house production or purchasing from outside suppliers. As far as marketing is concerned, the SIPLACE team’s business should benefit from the ASM Group’s close customer relationships in Asian markets. In this area, SIPLACE has been very successful with large, internationally operating customers, but has yet to make serious inroads with the large numbers of regional producers. Asked about his long-term and medium-term outlook, W. K. Lee referred to the in-house slogan, which employees of SIPLACE and ASM had selected for their wide range of integration projects: Together #1.

The SIPLACE solutions which are leading hardware and software and innovative service are able to react quickly and perfectly to all customer requirements.

ASM can provide everything down the production line, from wafer production to chip assembly and packaging to SMT placement.

For more information, visit www.siplace.com.

ASM Assembly Systems

At the beginning of 2011, the SIPLACE team (formerly Siemens Electronics Assembly Systems) became a business unit of ASM Pacific Technology and operates now as ASM Assembly Systems. With its SIPLACE machines and innovative manufacturing concepts, ASM Assembly Systems GmbH & Co. KG is the world’s leading manufacturer of surface mount technology (SMT) placement machines and solutions. Since its beginnings in 1985, the company has installed almost 25,000 placement machines at over 2,500 customers all over the world. Electronics manufacturers in all industries such as telecommunications, automotive, IT, consumer electronics and automation use and depend on SIPLACE's broad portfolio of solutions and services.

For more information about ASM Assembly Systems (SIPLACE), please visit www.siplace.com.

ASM Pacific Technology

As a subsidiary of ASM International based in Almere, Netherlands, ASM Pacific Technology (ASMPT), Singapore, has developed in only a few years into the world’s leading supplier of chip assembly, bonding and packaging systems and solutions. The ASMPT Group produces and markets machines for front-end and back-end chip assembly and semiconductor packaging. The company has plants in Hong Kong, China, Singapore and Malaysia, and since January 1, 2011 in Germany. ASMPT has been listed on the Hong Kong Stock Exchange since 1989.

ASMPT is one of the stocks in the Hang Seng HK MidCap Index under the Hang Seng Composite Index, the Hang Seng Information Technology Industry Index, and the Hang Seng Hong Kong 35 Index.