Micro LED and Mini LED related applications are in the spotlight of this year's Touch Taiwan International Smart Display Exhibition. Products showcased during the event included large-size Mini LED RGB outdoor displays, Mini LED backlight gaming displays, Micro LED automotive displays, and small-size wearable panels, demonstrating the technical strength of manufacturers.

These next-generation display applications feature fine images and vivid colors, which are the result of uniform arrangement of millions of LED dies on the driver backplane. However, the mass transfer and bonding of a large number of LEDs remains the key challenge for the industry chain.

Faced with the challenge of mass transferring, current solutions mostly integrate the manufacturing process technologies from each stage. Equipment manufacturers are among the key workers behind the scenes that drive the progress. They work with different companies in the industry to develop systematic solutions to realize innovative LED display applications.

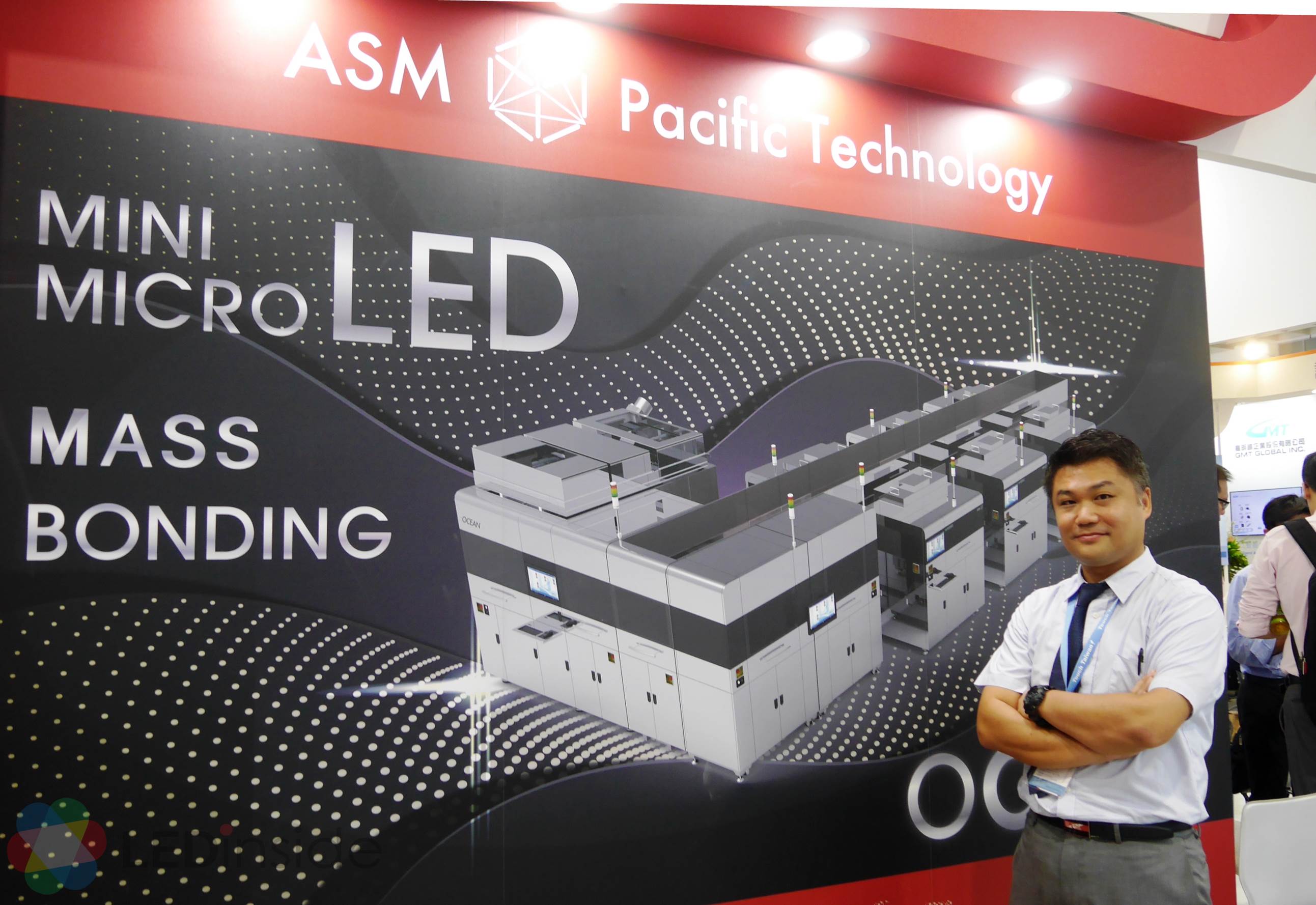

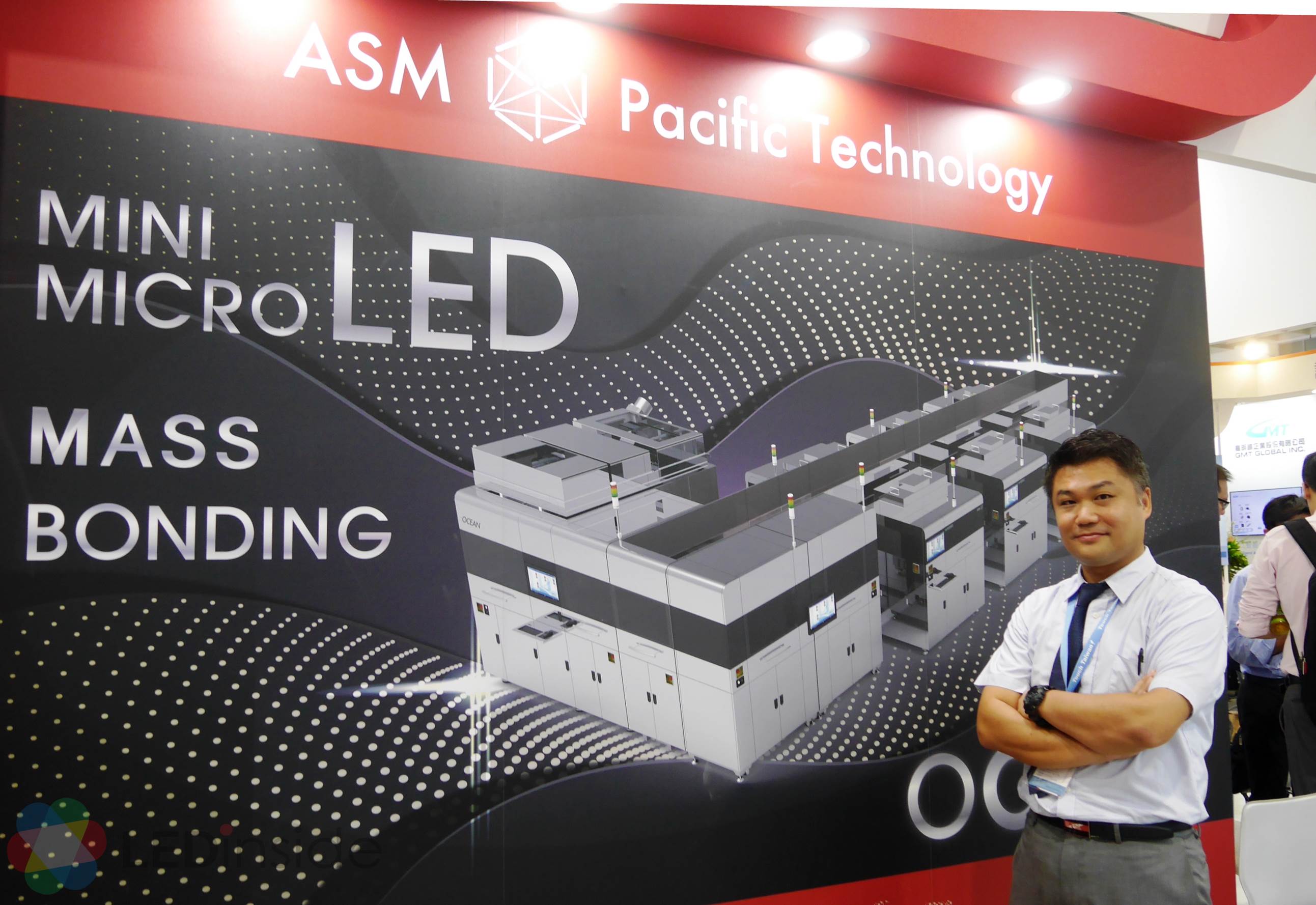

ASM Pacific Technology (ASMPT), who participated in the Touch Taiwan Exhibition this year, is one of these equipment manufacturers that push forward Micro LED and Mini LED technologies.

LEDinside interviewed Max Wong, Senior Business Development Manager at ASMPT, who gave us a detailed explanation on how ASMPT's Ocean Line automatic system integrates transferring and bonding process, optimizes flatness and uniformity of chip arrangement for Micro LED and Mini LED displays, and accelerates the commercialization of innovative display applications.

ASMPT Showcased Ocean Line, the Fully Automatic Production Line

The equipment is huge and weighs several tons, making it difficult to move it to the exhibition site. Therefore, ASMPT has adopted VR devices to demonstrate the actual operation of OCEAN Line in an immersive way.

Once wearing the VR glasses, the visitors would feel like being around the equipment. By using the smart joystick, they could move to different positions and look at the equipment from different aspects to learn more about the operation process. It was also possible to open the cover of the equipment to see how the internal mechanical arms re-allocate the LED dies, or to explore the automatic delivery system embedded in the equipment.

Using VR to Experience Ocean Line, the Fully Automatic Production Line

"Nowadays the customers have increasingly higher requirements for clean rooms, and our Ocean Line can be fully automatic without any manual work." Max stressed that ASMPT provides completely automatic production line to meet the demand for high yield of Micro/Mini LEDs. The automatic solution enables process from the feeding of epitaxy wafer all the way down to the RGB chip arrangement, transferring, and bonding without manual control. This production line can greatly improve the yield, reducing the production pressure of reprocessing, and optimizing the efficiency of manufacturing process and operation.

Mass Transferring and Bonding Technology Empowers Micro LED/Mini LED Manufacturing Process

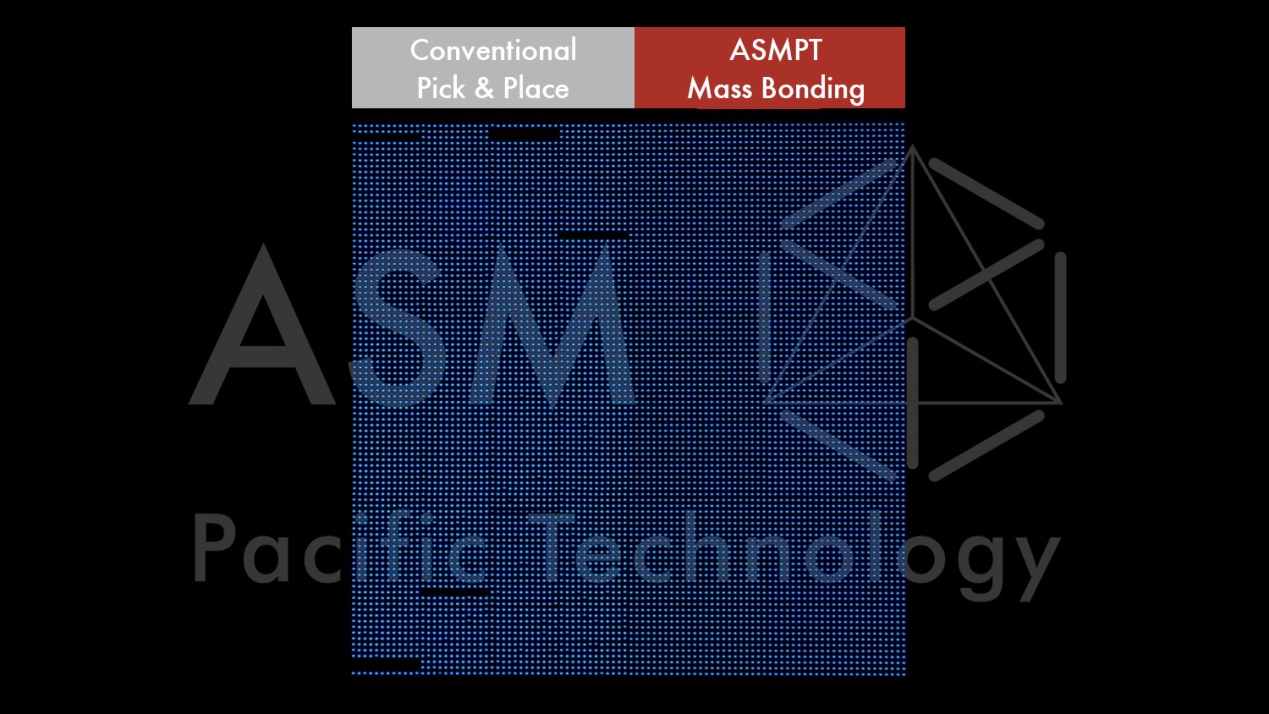

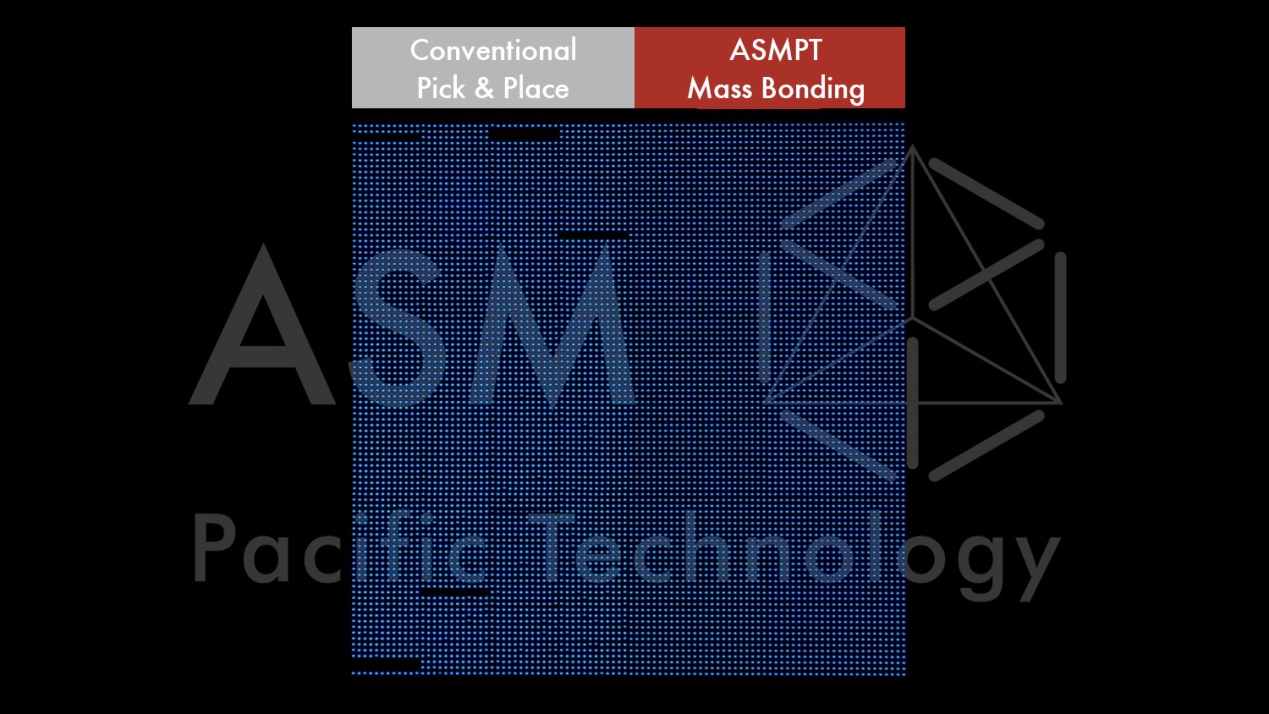

ASMPT also showcased its integrated solution for mass transferring and bonding, demonstrating how this solution differs from traditional pick and place technology.

Max points out that, with conventional techniques, LED dies are picked and placed onto the substrate one by one, and it is difficult to control the precise location and flatness of chips during reflow process. This would result in the different angles in which the LEDs cast their light so that the light is not uniformed. However, Ocean Line adopts AD300Pro which uses ASMPT’s patented technologies and enables mass transferring and bonding directly onto the substrates. This exclusive solution obviates the need for LED chips to go through reflow, ensuring the evenness of displays and increasing the overall brightness even a large number of LEDs are bonded at once.

(Top view photo provided by ASMPT)

(Side view photo provided by ASMPT)

"Our equipment solutions can be applied to three different display technology processes: Micro LED, Mini LED RGB and Mini LED backlight." Max also said that the Ocean Line solution enables precise die allocation, transferring and bonding, so that it can be used in current fine pitch displays. Moreover, the solution is suitable for Micro LED display applications with smaller die size and finer die pitch.

As the key worker behind the scenes that drive the development of Micro LED application, ASMPT delivers another key solution that enables mass transfer and bonding for Micro LED.

Max mentioned that the AD300Pro mass transferring and bonding solution is able to achieve 10,000+ Micro LED chips per transfer. Then the bonding of the large number of dies from the temporary substrate to the driver backplane is performed with a maximum bonding efficiency of 80,000+ units per run.

Micro/Mini LED Display Application is Ready to Take Off, ASMPT Prepares Production Capacity for Clients

"Most of the Micro LED products exhibited at Touch Taiwan this year are bonded by ASMPT’s equipment." Max noted that ASMPT is quite optimistic about the future development potential of Micro LED, and explosive market growth is expected in the next one or two years.

Micro LED applications have been showcased by leading manufacturers in major international exhibitions since last year. This year, the range of application for products covers large-size displays, mid-size automotive displays, transparent displays, and small-size wearable displays.

As an equipment manufacturer, ASMPT has been fully prepared to provide AD300Pro, the high-speed transferring and bonding solution in combination with Ocean Line, its fully automatic production line, which jointly enable the clients to seamlessly move from R&D to commercialized mass production.